ESD Trays

ESD Trays & ESD Containers

MFG Tray’s Fibrestat ESD product line encompasses a variety of trays, containers and specialty products molded from high-strength, glass-reinforced composites that are specifically formulated to dissipate electrostatic discharge and to safely and effectively convey, accumulate and store static-sensitive parts and assemblies.

The company’s ESD-safe conductive products have a surface resistivity of less than 10^5 to 10^6 ohms, and static dissipative products have surface resistivity between 10^5 to 10^11 ohms. MFG Tray Fibrestat products meet or exceed ANSI/ESD S20.20 standard for ESD protection. The high conductivity/low electrical resistance of MFG Tray’s composite material is a permanent property ensuring the safe transfer of electrostatic discharge away from sensitive microprocessors, assemblies, loaded circuit boards and other electronic components for the life of the tray or container.

Fibrestat ESD trays and ESD containers may be continuously used in temperatures ranging from -60° to 250° F (-51° to 121° C), and are resistant to cutting oils, greases, radiation, and mild acids and alkaline solutions within a pH rating of 3.0 – 10.0. Composite construction ensures exceptional strength and durability, and design features such as smooth surfaces and radial edges ensure safe, secure handling.

ESD Conveyor Trays: Tray design is ideal for component assembly and compatibility with conveyors or cart transport systems.

ESD Nesting Boxes with Lids: Nesting boxes are offered in a range of sizes to accommodate a wide range of components. Lids protect parts and enable containers to be stacked.

ESD Stacking Boxes: Stacking feature facilitates parts containment and space-saving product holding and storage.

ESD Nest and Stack Boxes: Nest-and-stack design is ideal for work-in-progress or distribution applications.

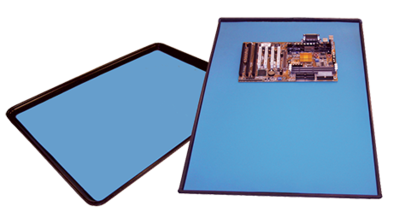

Tray Liners

ESD Rubber Tray Liner - 16"x24"x0.080"

The ESD tray liners are used to line the surface of process trays to keep items protected and from sliding around. ESD rubber provides a better path-to-ground and cushion versus the hard surface of the conductive tray. The economical dual layer rubber material is cut to fit a 16"x24" process tray. The 0.080" thick ESD tray liner has a dissipative top layer and a conductive bottom layer. Meets or exceeds requirements of ANSI ESD S541-2003. RoHS compliant. Stock is Light Blue, but it is also available in Dark Blue, Green or Gray with the following features:

Dissipative work surface: 10^6 - 10^8 ohms Rtt

Thickness: 0.080 Inches

Resistance to Ground: 8 x 10^6-8 ohms

Resistance Point to Point: 2 x 10^6-8 ohms

Trays for Industrial and Process Applications

Molded Fiber Glass Tray Company’s Toteline™ is comprised of over 300 differentmaterial handling trays, containers and wash boxes for material handling and processing solutions in an array of industries, including chemical, rubber, metalworking, machinery, electronics, transportation and utilities.

MFG Tray material handling trays and containers are dimensionally stable under heavy loads and readily integrate with machine and robotic applications. Unlike metal they will not bend, dent or corrode, and they are impervious to cutting oils, grease, radiation, and mild acids and alkaline solutions. They may be used continuously in temperatures ranging from -60° to 250° F (-51° to 121° C), and intermittently in temperatures of 300° F and higher.

Nest and Stack Containers: Nest and stack containers are ideal for heavy-duty storage, work-in-process or distribution applications.

Stacking Containers: MFG Tray offers the widest variety of composite stacking containers in the industry to serve an array of material handling needs.

Nesting Containers: Versatile nesting design enables these trays to serve as drawers, trays, pans or stock boxes for more efficient material handling in a variety of applications and compact storage when not in use.

Wash Boxes: Strong, stackable wash boxes feature integral drain holes and slots to simplify washing, draining and storage of small parts.

Conveyor and Assembly Trays: The low-profile design of these containers readily integrates with conveyors and rack storage systems in various industrial and processing applications.

Ventilation Trays: These trays are designed to optimize air flow and reduce drying and cooling times while ensuring solid stacking without sag or bending.