Packaging

Bags

What is the difference between Static Shielding and Anti-Static bags?

Silver Static Shielding bags offer a metalized layer called a Faraday cage that shields the contents from a static charge. An Anti-Static bag is made of a neutral material that does not generate nor shield from static.

Static Shielding

This transparent metal-in static shielding bag is designed to provide a static safe environment for sensitive electronic devices. Bags are printed with an ESD protective symbol and a lot code for traceability. Open top and ZipTop styles are available. The bags are heat sealable. Static Shielding Bags are manufactured from a polyester, metal, polyethylene laminate. The polyester dielectric in concert with the metal layer provides discharge shielding. The exterior being static dissipative allows electrostatic charges to be removed when grounded.

Moisture Barrier

Moisture Barrier Bag is designed for dry packaging of electronic devices and uses the first structure. The moisture bag replaces costly nylon/foil laminates with metallized polyester and offers the strongest price/performance relationship in the dry packaging of moisture sensitive devices. The moisture bag offers full protection from ESD, static fields and tribocharging.

Anti-Static Poly Bags and Tubing

It is humidity independent, N-Octanoic acid free, does not promote corrosion and has no measurable outgassing. This material meets the electrical & physical properties of PRF-81705D Type II.

Black Conductive Poly Bags and Tubing

Contains a black color additive. Manufactured with a proprietary blend of 100% virgin low and linear low density polyethylene and a conductive additive. Meets the conductivity requirements of MIL-P-82646 Rev B. You cannot see through this product in interior light.

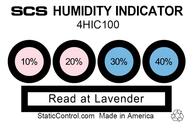

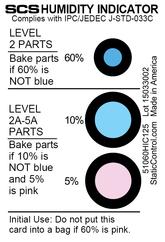

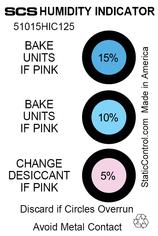

Humidity Indicator Cards

Humidity Indicator Cards (HIC) are printed with moisture sensitive spots which change color from blue to pink when exposed to a relative humidity level.

HUMIDITY INDICATOR CARD CHART

| Item Number | Size | Number of Spots | Relativity Humidity Levels | Quantity per Metal Can |

| 51060HIC125 | 2"x 3" | 3 | 5/10/60 | 125 |

| 51015HIC125 | 2"x 3" | 3 | 5/10/15 | 125 |

| 3HIC125 | 2"x 3" | 3 | 30/40/50 | 125 |

| 4HIC100 | 3"x 2" | 4 | 10/20/30/40 | 100 |

| 6HIC200 | 1 9/16"x 4 3/4" | 6 | 10/20/30/40/50/60 | 200 |

Desiccants

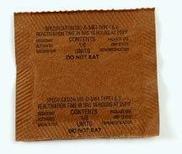

Kraft Paper Desiccant

Desiccant works by efficiently absorbing airborne moisture left inside the bag after vacuum sealing, and captures moisture that manages to pass through the bag material.

Kraft Desiccant Sizing Chart

| Part Number | Unit | Qty | Container | Weight | Bag Dimensions |

| 02BS10R13 | 1/6 | 1,200 | 5 Gal Pail | 20 | 2.75 x 2.250 |

| 02BK10R13 | 1/3 | 700 | 5 Gal Pail | 22 | 3.125 x 2.375 |

| 02BL10R13 | 1/2 | 550 | 5 Gal Pail | 24 | 3.5 x 2.375 |

| 02BM10R16 | 1 | 1,300 | 30 Gal Drum | 128 | 4.5 x 3.0 |

| 02BM10R13 | 1 | 300 | 5 Gal Pail | 27 | 4.5 x 3.0 |

| 02BN10R16 | 2 | 800 | 30 Gal Drum | 150 | 4.5 x 5.0 |

| 02BN10R13 | 2 | 150 | 5 Gal Pail | 32 | 4.5 x 5.0 |

| 02BO10R16 | 4 | 500 | 30 Gal Drum | 156 | 6.250 x 5.0 |

Tyvec Pouch Desiccant

Tyvec desiccant begins it’s work by absorbing air borne moisture left inside the bag when you’ve finished vacuum packaging. Then it captures moisture that manages to pass through the bag material. Secured in a strong envelope of either clean room compatible, sulphur-free Tyvek desiccant helps keep your devices dry, even through unexpected shipping delays or longer than anticipated storage time.

| Part Number | Unit | Qty | Container | Weight | Bag Dimensions |

| 02BS10A13 | 1/6 | 1,200 | 5 Gal Pail | 20 | 2.125 x 2.125 |

| 02BK10A13 | 1/3 | 700 | 5 Gal Pail | 22 | 2.5 x 2.125 |

| 02BL10A13 | 1/2 | 550 | 5 Gal Pail | 25 | 2.875 x 2.125 |

| 02BM10A16 | 1 | 1,800 | 30 Gal Drum | 127 | 4.5 x 3.0 |

| 02BM10A13 | 1 | 300 | 5 Gal Pail | 28 | 4.5 x 3.0 |

| 02BN10A16 | 2 | 800 | 30 Gal Drum | 135 | 4.5 x 5.0 |

| 02BN10A13 | 2 | 150 | 5 Gal Pail | 32 | 4.5 x 5.0 |

| 02BO10A16 | 4 | 500 | 30 Gal Drum | 156 | 6.25 x 5.0 |

| 02BQ10A16 | 8 | 300 | 30 Gal Drum | 194 | 8.25 x 4.5 |

| 02BR10A16 | 16 | 150 | 30 Gal Drum | 184 | 11 x 4.5 |